External floating roof tanks are designed with a rim sealing system.

Floating roof design considerations.

The choice between a single deck design and a double deck design requires an assessment of site wind loading conditions rainfall intensity and frequency and history of prior wind damage to floating roofs.

Determine desired working volume.

The obeyed methodology of this study is by calculating the center of gravity and moment of inertia of the floating roof in each case.

Daily throughput x resupply interval safety factor.

Aggressive cycle frequency puts considerable strain on a floating roof especially the rim.

Check requirements state web page.

Operational plans are a key consideration in your floating roof and seal choices.

Group of floating roof tanks.

We can design the floating roof to cover the whole liquid surface except the small annular space between the shell and the deck.

See more ideas about roof design sliding glass door architecture.

Both cycle frequency and inlet outlet rates of the tank will help determine the best material options.

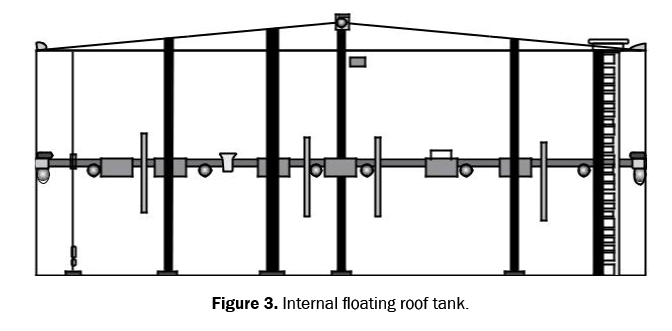

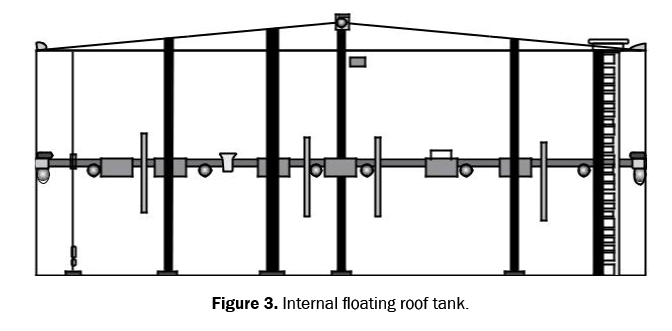

The deck can be made to float on the liquid directly or rest above the surface on pontoons.

Options for foundation design.

The first consideration is chemical compatibility.

Large diameter floating roofs are efficient structures but require safe operating practices that are supported by effective inspection and maintenance programs.

Fixed cum floating roof tanks shall be treated as fixed roof tanks.

Hidden considerations for aluminum floating roof design conclusion hmt inc.

In the shell design analysis shell stress design will be performed taking into consideration of all the considerably loading including hydrostatic pressure wind loading and seismic loading.

Following are some key considerations for selecting and designing floating roof seals above and beyond the existing standards that will help ensure asset longevity engineered safety and optimal working efficiencies.

Group of fixed roof tanks.

Group containing both fixed roof tanks floating roof tanks shall be treated as fixed roof tanks.

In this study three cases were applied to analyze the buoyancy of the floating roof in each case.

To study roof pontoons design a buoyancy analysis of the floating roof was established with punctured pontoons.

Class a and or class b petroleum products same dyked enclosure.

24 waterway avenue suite 400 the woodlands texas 77380 ph.

Establish product whether or not internal floating roof will be used and type dimensions of ifr.

Poor maintenance of floating roofs can have severe operational impact.

The history of floating roof operations has been generally.

The storage tank design consists of two major designs that is 1 the shell design analysis and 2 the floating roof design.